-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Product Material | ABS, PC, PVC, PA66, POM Or Other You Want | Process | Plastic Injection Mold |

|---|---|---|---|

| Mold Base | LKM, C50 Standard Mold Base Or Other You Want | Standard | HASCO, DME, MISUMI, PUNCH |

| Certificated | ISO 9001:2008 Certificated, GSG Certificated | Mould Precision | 0.1 MM |

| Service | OEM Service | Service | OEM/ODM |

| Tolerance | ±0.01mm | ||

| Highlight | Interphone Precision Injection Molding,0.1 Mm Precision Injection Mould,DME Plastic Injection Molding Parts |

||

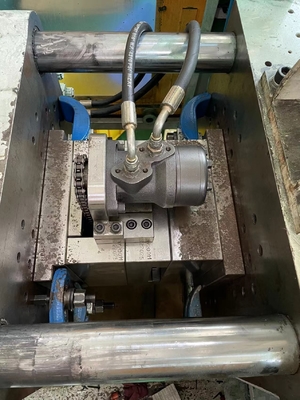

PC / PP / POM Plastic Injection Mold , Plastic Interphone Mould With LKM / DME / HASCO Base

plastic injection auto part mould advantages:

1.Professional design team

2.Professional mold design team

3.Professional mold making machines

4.Professional mould and product QC and tec. team

5.Rich mould making experience with different clients from various country

Plastic injection auto part mould Special info.:

| Brand | WEI YU |

| Model | WY-DCAM-47 |

| Process | Plastic injection mold |

| Mold Base | LKM, C50 standard mold base or other you want |

| Mold Material | H13, 1.2344, 1.2738 and so on to be chosen |

| Standard | HASCO, DME, MISUMI, PUNCH |

| Product Material | ABS, PC, PVC, PA66, POM or other you want |

| Certificated | ISO 9001:2008 Certificated, GSG Certificated |

Our professional engineers team design, make and check the mold in each step:

- Our engineers follow the molds' production every week to make sure all of them are in schedule;

- After trial production, we will check the samples to make sure all are right

- We will send the sample and dimension report to our clients for approval

- After everything is ok, we will do final inspection on the molds and products before shipment.

Mold material Aluminum, 45#, P20, H13, 718, 1.2344, 1.2738, etc.

Plastic material PC/ABS, ABS, PC, PVC, PA66, POM or other as you want

Silicone rubber material NR, NBR, SBR, EPDM, IIR, CR, SILICONE, VITON, etc.

Plastic Finishing Polished, Textured, Glossy Finished, Painted, Slik Printed, Rubber Painted, etc.

Drawing formats IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.

plastic RAL PANTONE color contrast method

ISO 9001:2015 certification, SGS certification

Service items Provide production design, production and technical services, mold development and processing, product assembly and packaging, etc.

Market Scope Industrial, Consumer Goods, Food Processing, Aerospace, Seals/Gaskets, Lighting, Packaging, Filters, Healthcare, Telecommunications, Machinery, Water Treatment, Appliances, Recreation, Lawn and Garden, Education, Oil and Gas, Government, Construction, piping, monitoring, pumps, ships, motors, gears, RFID tags, electronics and fasteners.

Below are some pictures about this mold and its product, hope you could have a look:

![]()

![]()

![]()

![]()

![]()