-

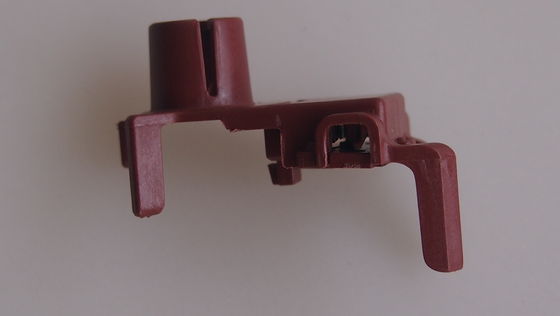

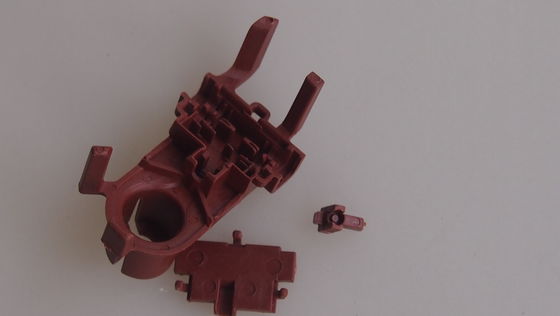

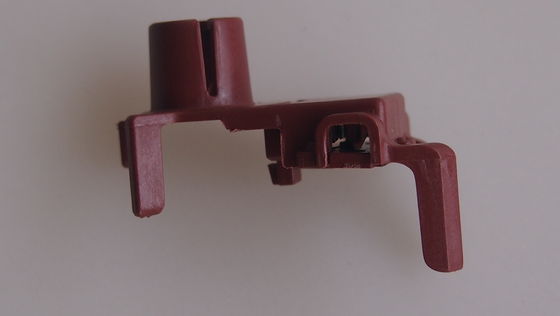

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Plastic Modling Type | Injection | Material | ABS,PC,POM,PP,PE |

|---|---|---|---|

| Color | Black,Gray,White,According To The Color Card,Custom As Requirement | Product Name | Plastic Electronic Enclosure,High Precision Innovative New Plastic Injection Molding Products,High Precise PP PC ABS Molding Injected Plastic Products,Plastic Medical Helmet Parts,Custom Small Plastic Engineering Parts/ Oem Injection Molding Products |

| Size | Customized Size,can Be Designed According To Your Need | Design Software | CAD,UG,Pro-E,CAD UG CAM,PRO |

| Application | Household Appliances,Protect,Home Use,Household Appliances Or Vehicle Application,Auto Parts | Surface Finish | Chrome Plating,Testure/Sand/MT/YS/SPI/EDM Finish,Texture/Sandy/MT/YS/SPI/EDM Finish/smooth/glossy,Texture,etc |

| Mould Life | 300000-1000000 Shots,250000-300000shots | Type | Plastic Injection Molding,Smooth,OEM Parts,injection |

| Surface Treatment | Polishing,Electroplating,no Burr,Texture,Plating Teflon Etc | Runner | Hot Runner\ Cold Runner,Hot/cold Runner System Per Request |

| Cavity | Multi,Single/multi Per Request,1*2,Single/Multi | ||

| Highlight | Precision Injection Molding,GF Precision Injection Molding,PA66 complex plastic injection molding |

||

Durable PMMA , PA66 + GF Plastic Precision Injection Molding High Polish , Commodity Mould

Specifications

plastic injetion case mould

high quality injection moulding

ISO9001:2008 certificated

CNC, EDM & MMM Measurement System

Welcome to visit Weiyu Mould CO.,LTD

|

PLASTIC INJECTION Mould standard |

HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

|

Mould base |

LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

|

Material main core and cavity insert |

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Hardness of steel |

46~56HRC |

|

Material for Slider ,Lifter and all sub insert use |

1.2767 HRC |

|

Cavity |

Single-cavity ,Multi-cavity |

|

A surface request: |

EDM & High Polish |

|

Gate |

Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

|

Maximum mould size |

1500*1500 mm |

|

Mould life time |

500000~+1,000,000 shots |

|

Quality |

ISO9001-2008 certification |

|

Product material |

PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

|

Lead time |

4~7 Weeks |

|

Package |

Wooden/Plywood case for tool ,PE bags add export carton for parts |

|

Payment terms |

T/T |

|

Trade terms |

FOB SHENZHEN,EXW ,CIF |

|

Export country |

Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

|

Value-added service |

Polish,texture,painting,screen printing,turnkey project |

We are specialized in

- Design and making precision plastic mold

- Developing and producing Double Color plastic parts

- Mass Production of plastic injection parts

As a professional manufacturer, our range products are covered from computers, communications, household appliances, medical appliances, motor vehicle accessories, IT related products and so on.

Basic Information

| Business Type: | Manufacturer | |

| Product/Service (We Sell): | Injection molds design and fabrication,Mass production,Engineering,Plastic injection,Plastic tooling,Export mold,Auto mold,Two color injection molding,Office plastic product,Plastic electronic parts,Medical plastic parts,Auto parts,Mold Design,Aluminum Molding,Zinc Mold,Die Casting Mold,Precision product,Precision mold,Hasco mold,DME mold | |

| Number of Employees: | 101 - 200 People |

| Factory Size (Sq.meters): | 3,000-5,000 square meters | |

| QA/QC: | In House | |

| Number of Production Lines: | 1 | |

| Number of R&D Staff: | 21 - 30 People | |

| Number of QC Staff: | 11 - 20 People | |

| Management Certification: | ISO 9001:2000 ISO 9001:2008 | |

| Contract Manufacturing: | OEM Service Offered Design Service Offered Buyer Label Offered |

Equipment:

CNC Milling Machine, CNC Wire Cutting, Traditional Milling Machine, and Plastic Injection Molding Machine

Plastic precision mould

We sell percision plastic injection steel moulds to our customers, and our plastic products include bottle embryos, bottle caps, DVD boxes, head lamps & tail lamps housings & radiators grilles for cars, notebook housings, printer & ink cartridges, LCD light panel sets, digital camera components, food containers, LCD TV outer housings, household appliance outer housings, PDA outer housings, mobile phone outer housings, Bluetooth stereo headset outer housings, web-based digital tablet terminal housings, medical terminal outer housings, washbasins, buckets, sinks and tire covers.