-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Plastic Modling Type | Injection | Material | ABS,PC,POM,PP |

|---|---|---|---|

| Color | Black,Gray,White,According To The Color Card,Custom As Requirement | Product Name | Plastic Electronic Enclosure,High Precision Innovative New Plastic Injection Molding Products,High Precise PP PC ABS Molding Injected Plastic Products,Plastic Medical Helmet Parts,Custom Small Plastic Engineering Parts/ Oem Injection Molding Products |

| Size | Customized Size,can Be Designed According To Your Need | Design Software | CAD,UG,Pro-E,CAD UG CAM,PRO |

| Application | Household Appliances,Protect,Home Use,Household Appliances Or Vehicle Application,Auto Parts | Surface Finish | Chrome Plating,Testure/Sand/MT/YS/SPI/EDM Finish,Texture/Sandy/MT/YS/SPI/EDM Finish/smooth/glossy,Texture,etc |

| Mould Life | 300000-1000000 Shots,250000-300000shots | Surface Treatment | Polishing,Electroplating,no Burr,Texture,Plating Teflon Etc |

| Highlight | 300000shots Precision Injection Molding,YS Precision Injection Molding,POM plastic injection molding parts |

||

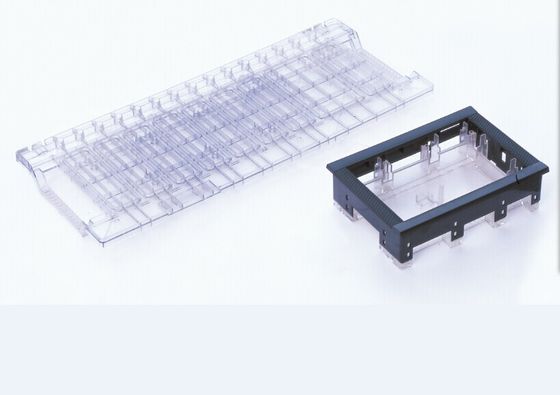

Custom ABS PC Plastic Precision Injection Molding For Electronic Parts plastic injection molding parts

Packaging & Delivery

| Packaging Detail: | wooden case |

| Delivery Detail: | 2-8 weeks |

Specifications

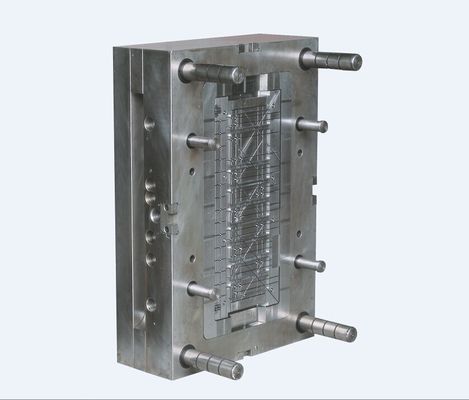

Plastic injection mould for electronic part

Mould Standard: Hasco,Dme and Misumi Ava

Features: High Precison

High precision plastic injection mould/mold for Electric/Electrical/Electronic parts

Feature of the product:

--- High accuracy

--- Durable

--- Unique structure

--- High quality with mould line standard

--- Mature, perfect and excellent moulds with reasonable design

Our business scope:

1. Plastic mold design & fabrication

2. Injection moulding

3. Secondary operation

Process:

1. Quote competitive price according to customer's detailed requirement.

2. Sign agreement.

3. Customer T/T deposit to us to start to design mould.

4. Send mould drawing to customer for confirmation.

5. Mould design confirmed and start to make mould.

6. Make mould trial during tooling time ( Which we get agreement with customer).

7. Send mould trial sample to customer for inspection. Or customer come to our factory to

inspect mould personally.

8. Customer T/T balance to us after mould confirmed.

9. Deliver mould after get balance.

Our Services

Weiyu's full service menu offers customers a One-Station solution from product design through finished part qualification and production.

Available as selected services or as a whole service package, we tailor our offerings to meet

the scope of your specific projects for

a . Plastic Part Design

b . Mould Manufacture

c . Plastic Injection Molding

d . Prototyping

e . Electroplating

f . Precision Components of Moulds

|

Our Strengths

|

|

|

1 |

Rich experience on mould design and project management with dedicated team to serve worldwide clients. |

|

2 |

Extensive experience in tooling for industries including Automotive,TV,Medical,home appliance,household,aviation,etc. |

|

3 |

Powerful facilities and equipment serve the clients from mould design to injection moulding of mass production. |

|

4 |

Huge production capacity that can produce 500sets high precision molds worldwide. |

|

5 |

Professional personnel "know-how" to serve clients with high quality products at lower cost(Mold runs dimensionally precise,high efficiency,stable and easy maintenance,etc) |

|

6 |

Worldwide supply chain aligned for specified materials(mould steel,copper,plastic resins,injection moulding technologies,etc.) |

|

7 |

Strong experiences in mould & moulding engineering,hot runner system, over molded,IML moulding,gear,multi-cavity,transparent parts,etc.) |