-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

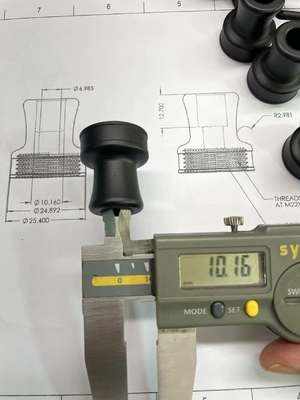

| Product Material | Plastic,Steel | Product | Household Appliance |

|---|---|---|---|

| Design Software | Solidworks | Mould Material | P20/718/738/NAK80/S136 |

| Cavity | Single Cavity / Multi Cavity | Runner | Hot Runner\ Cold Runner |

| High Light | P20 Plastic Injection Mold Parts,Single Cavity Plastic Injection Mold Parts,Single Cavity Automotive Plastic Parts |

||

1 . Plastic injection mould

2 . Material: ABS/PP/PE/PS/POM/PA6/PU/PMMA etc.

3 . Application: Electronics; Medical device; Household appliance; Security products; Vending Machine, etc.

4 . Single / Multi cavity

5 . Plastic injection mould

Description:

|

Material: |

ABS/PP/PE/PS/POM/PA6/PU/PMMA etc. |

|

Size: |

Customized size |

|

Color: |

Any colors |

|

MOQ: |

Negotiable |

|

Application: |

Electronics; Medical device; Household appliance; Security products; Vending Machine, etc. |

|

Package: |

Inner is pp bag, outer is paper carton, or customized. |

|

Material: |

ABS/PP/PE/PS/POM/PA6/PU/PMMA etc. |

|

Size: |

Customized size |

|

Color: |

Any colors |

|

MOQ: |

Negotiable |

|

Application: |

Electronics; Medical device; Household appliance; Security products; Vending Machine, etc. |

|

Package: |

Inner is pp bag, outer is paper carton, or customized. |

|

Plastic Mold (Moulds) production process |

Description |

| 1. 3D Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations |

Including the price of molds, molds sizes, material for cores & cavities, weight of product, part cost, payment, mold lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mold design and quotation. |

| 4. Making mold(moulds) |

Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer a mold progress(picture). |

| 6. sample shoot |

We provide the molds test samples for confirmation (about 10-15 piece), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirement. |

| 8. Delivery | deliver goods by air or by sea. |