-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Lead Time | 15-30 Days | Surface Finish | Smooth |

|---|---|---|---|

| Molding Type | Injection Molding | Product Size | Customized |

| Application | Automotive | Mold Life | 500,000-1,000,000 Shots |

| Material | Plastic | Color | Customized |

Product Description:

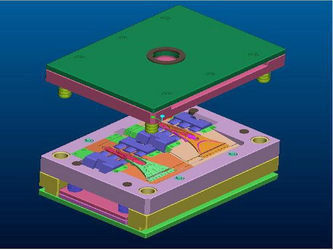

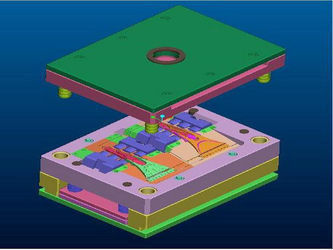

Automotive Injection Molding is a manufacturing process for producing vehicle parts and components by injecting molten plastic resin into a mold cavity. It has a smooth surface finish, and the size of the product can be customized to fit the needs of the customer. The molding process is efficient and cost-effective, as it can be used to produce multiple components from a single multi-cavity mold. In addition, the mold life can be expected to be between 500,000 and 1,000,000 shots, depending on the material used. Automotive Injection Molding is a great solution for producing vehicle components from plastic materials such as ABS, PC, and POM.

Features:

- Product Name: Automotive Injection Molding

- Product Size: Customized

- Package: Carton/Wooden Case

- Transportation: By Sea/Air/Express

- Molding Type: Vehicle Injection Molding

- Tolerance: ±0.02mm

Technical Parameters:

| Parameter | Value |

|---|---|

| Material | Plastic |

| Lead Time | 15-30 Days |

| Design | Customized |

| Application | Automotive |

| Molding Type | Injection Molding |

| Surface Finish | Smooth |

| Product Size | Customized |

| Mold Life | 500,000-1,000,000 Shots |

| Cavity | Multi-Cavity |

| Transportation | By Sea/Air/Express |

Applications:

Automotive Injection Molding is a type of molding used for manufacturing automotive parts and components. It involves injecting plastic or other materials into a multi-cavity mold to create the desired shape. This type of molding is widely used in the automotive industry due to its ability to produce parts with high accuracy and tight tolerances. Automotive Injection Molding offers a cost-effective solution for producing large quantities of parts quickly and efficiently. It can also be used to create complex shapes and intricate details. Automotive Injection Molding is a reliable and durable process that is capable of producing parts with a wide range of properties. The parts manufactured using this process can be transported by sea, air, or express and are usually packaged in cartons or wooden cases.

Customization:

- Lead Time: 15-30 Days

- Molding Type: Injection Molding

- Package: Carton/Wooden Case

- Application: Automotive

- Material: Plastic

We provide reliable and high quality Custom Automotive Injection Molding Services for vehicle parts. We specialize in Vehicle Injection Molding and Automotive Injection Molding Services which are customized to your specifications. Our experienced professionals use the latest technologies to ensure that your parts are produced with accuracy and precision. We provide you with secure packaging options like Carton/Wooden Case for your parts. We use quality Plastic materials which are durable and long lasting.

Support and Services:

We provide technical support and service for Automotive Injection Molding products, helping customers to get the most value out of their investment. Our support team consists of experienced engineers and technicians who are familiar with a wide range of injection molding applications.

We provide assistance with selecting the right molding materials and machines, troubleshooting and resolving technical issues, and optimizing process parameters. Our team can also provide guidance on design for manufacturability and help with tooling and prototyping.

We offer flexible service plans and support packages, with options ranging from remote support to onsite assistance. Our team is available 24/7 to answer any questions or provide help with your injection molding needs.

Packing and Shipping:

Automotive Injection Molding products are shipped using an industrial packaging service. The packaging materials used for the product are designed to protect the product from shock, vibration, and moisture. The product is then securely wrapped and the package is sealed with strong adhesive tape. The shipping service selected for the product is one that is reliable and cost-effective.

The product is shipped with full tracking and insurance. All packages are labeled with the correct shipping and delivery information. The delivery address is checked for accuracy before the product is shipped.

The product is also inspected before shipping to ensure that it meets all quality standards. Any defects are identified and fixed before the product is shipped. The customer is kept informed about the progress of the shipment via email or text message.

FAQ:

Q1: What is automotive injection molding?

A1: Automotive injection molding is a manufacturing process for producing parts from thermoplastic and thermoset plastics. It is commonly used to produce components for cars, buses, trucks, and other vehicles.

Q2: What advantages does automotive injection molding have?

A2: Automotive injection molding has several advantages over other manufacturing processes. It allows for precise, consistent, and repeatable parts with high dimensional accuracy. The process is also relatively fast, cost-effective, and highly automated, allowing for large scale production.

Q3: What types of materials can be used in automotive injection molding?

A3: Automotive injection molding can use a variety of thermoplastic and thermoset materials, including ABS, polypropylene, polycarbonates, polyethylene, and nylon. The type of material used will depend on the specific application.

Q4: What is the injection molding cycle time?

A4: The injection molding cycle time is the total amount of time it takes for a part to be produced. This includes the time it takes to inject the material, cool the part, and eject the part from the mold. Cycle times can range from a few seconds to several minutes depending on the part size and complexity.

Q5: What is the difference between overmolding and insert molding?

A5: Overmolding is a manufacturing process in which a second material is injected over the top of a previously molded part. Insert molding is a process in which a pre-molded part is inserted into the mold and then additional plastic is injected around it. Both processes are used in automotive injection molding.