-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Molding Type | Injection Molding | Surface Finish | Smooth |

|---|---|---|---|

| Transportation | By Sea/Air/Express | Tolerance | ±0.02mm |

| Application | Automotive | Package | Carton/Wooden Case |

| Material | Plastic | Color | Customized |

Product Description:

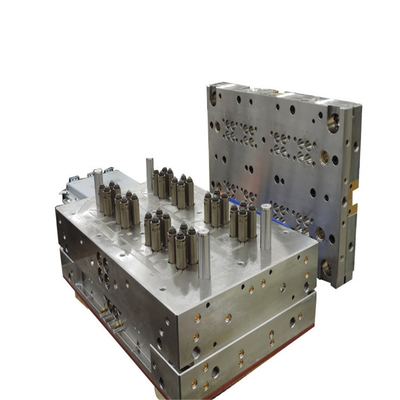

Automotive Injection Molding is a specialized manufacturing process used to produce intricate parts and components with complex geometries. It is ideal for producing high-precision parts for vehicles and automotive components, such as bumpers, door panels, and dashboards, with a multi-cavity design that is customized to meet the customer's exact specifications. Vehicle Injection Molding offers a fast lead time of 15-30 days, excellent tolerance of ±0.02mm, and packages the finished product in a sturdy carton or wooden case for shipping.

The Vehicle Injection Molding process is highly efficient and cost-effective, and it ensures high precision and reliability while achieving a short lead time. It is an ideal solution for producing high-quality parts with complex geometries, and it can produce parts with a variety of designs and materials. With its precision and short lead time, Vehicle Injection Molding is a great option for automotive manufacturers who need parts and components that are customized to their exact specifications.

Features:

- Product Name: Automotive Injection Molding

- Molding Type: Injection Molding

- Cavity: Multi-Cavity

- Transportation: By Sea/Air/Express

- Surface Finish: Smooth

- Mold Life: 500,000-1,000,000 Shots

- Keywords: Auto Injection Molding, Automotive Injection Molding, Vehicle Injection Molding

Technical Parameters:

| Parameter | Details |

|---|---|

| Material | Plastic |

| Transportation | By Sea/Air/Express |

| Application | Automotive |

| Cavity | Multi-Cavity |

| Color | Customized |

| Package | Carton/Wooden Case |

| Surface Finish | Smooth |

| Product Size | Customized |

| Lead Time | 15-30 Days |

| Design | Customized |

Applications:

Automotive Injection Molding is a manufacturing process used to create custom auto parts by injecting molten material into the mold in order to create a product with a predetermined shape. It is often used to create car body parts, engine components, and other automotive components. The process of automotive injection molding involves creating a detailed mold, which is then filled with molten material such as plastic or metal. This molten material is then injected into the mold to form the desired product. Transporting Automotive Injection Molding can be done by sea, air, or express. The package of Automotive Injection Molding can be done by carton or wooden case. The product size of Automotive Injection Molding can be customized according to the customer's needs. The main molding type of Automotive Injection Molding is injection molding. The surface finish of Automotive Injection Molding is usually smooth, which ensures the product has a perfect look.

Customization:

We specialize in providing custom auto injection molding services with high-quality parts for automotive applications. Our parts are made with precision and accuracy, with tolerance up to ±0.02mm. Our multi-cavity molds are packaged with carton or wooden cases for protection.

Our services are tailored for automotive industries, enabling you to get the perfect parts for your applications. We have the ability to create parts with intricate details and complex shapes.

For more information on our Automotive Injection Molding services, contact us today.

Support and Services:

We provide a range of technical support and services for the automotive injection molding industry. Our experienced team of engineers have the expertise to provide technical advice, troubleshooting assistance, and design and installation of new or upgraded injection molding systems. We can assist you with the most advanced injection molding processes, tooling, and materials.

Our technical support and services for automotive injection molding include:

- Equipment Selection and Sizing

- Process Optimization and Troubleshooting

- Tooling Design and Troubleshooting

- Material Selection and Troubleshooting

- Design and Installation of Automation Systems

- System Upgrades and Enhancements

- Maintenance and Repair Services

We strive to provide our customers with the highest quality support and services to ensure the success of your automotive injection molding projects.

Packing and Shipping:

Automotive Injection Molding Packaging and Shipping:

Automotive Injection Molding products are packaged and shipped in a protective manner in order to ensure they arrive at their destination in good condition. Products are securely sealed in corrugated cardboard boxes with inner packaging to protect the product from damage or dirt. These boxes are then placed in larger cardboard boxes with cushioning material to ensure further protection. The larger boxes are then labeled and shipped to the customer's destination.

FAQ:

- Q:What is Automotive Injection Molding?

- A:Automotive Injection Molding is a process of forming plastic parts using a mold and injection molding machine.

- Q: What are the advantages of Injection Molding?

- A:Injection Molding is cost-effective, produces high-quality parts, and can be used to produce complex parts with intricate details. Additionally, it is highly efficient and can produce large quantities of parts quickly and accurately.

- Q: What kind of materials can be used in Injection Molding?

- A:Many different materials can be used in Injection Molding, such as polypropylene, nylon, and ABS.

- Q: How long does the Injection Molding process take?

- A:The Injection Molding process typically takes anywhere from 15 seconds to several minutes, depending on the size and complexity of the part.

- Q: What is the process of creating a part with Injection Molding?

- A:The process of creating a part with Injection Molding consists of feeding melted plastic material into a mold, where it is cooled and then ejected from the mold.