-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Product Material | Plastic,Steel | Product | Household Appliance |

|---|---|---|---|

| Design Software | Solidworks | Mould Material | P20/718/738/NAK80/S136 |

| Cavity | Single Cavity / Multi Cavity | Runner | Hot Runner\ Cold Runner |

| Highlight | PMMA Auto Parts Molding,H13 Auto Parts Molding,PMMA Plastic Injection Components |

||

1 . Plastic injection mould

2 . Material: ABS/PP/PE/PS/POM/PA6/PU/PMMA etc.

3 . Application: Electronics; Medical device; Household appliance; Security products; Vending Machine, etc.

4 . Single / Multi cavity

5 . Plastic injection mould

Description:

|

Material: |

ABS/PP/PE/PS/POM/PA6/PU/PMMA etc. |

|

Size: |

Customized size |

|

Color: |

Any colors |

|

MOQ: |

Negotiable |

|

Application: |

Electronics; Medical device; Household appliance; Security products; Vending Machine, etc. |

|

Package: |

Inner is pp bag, outer is paper carton, or customized. |

|

Material: |

ABS/PP/PE/PS/POM/PA6/PU/PMMA etc. |

|

Size: |

Customized size |

|

Color: |

Any colors |

|

MOQ: |

Negotiable |

|

Application: |

Electronics; Medical device; Household appliance; Security products; Vending Machine, etc. |

|

Package: |

Inner is pp bag, outer is paper carton, or customized. |

Feature Of Plastic Injection Mold

- Plastic injection mold

- cover or Lid parts

- PP material

- 1*4 injection mold

- H13 (HRC48-52) Steel

- YUDO Hot runner

- Full hot runner

- Automatically running

- HASCO standard

- Short cycle time

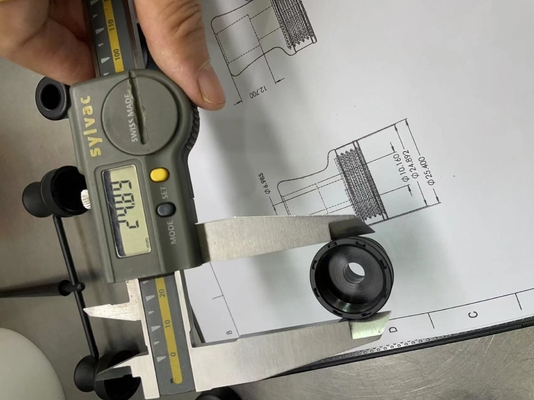

1, Start from part design analysis.

2, Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3, If product is complex, moldflow report will be present as well.

4, In house mold making shop ensure you mold quality under well control.

5, Normally it takes 20-40 days to make mold, precise time depends on part design.