-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Material | Stainless Steel: NAK80,S316,2344 Etc. | Finishing | Polishing, Anodize, Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating, Electrophoresis, Delta Seal, Delta Tone |

|---|---|---|---|

| Mould Precision | 0.1 Mm | Runner System | Hot Runner ,cold Runner |

| Place Of Origin | Dongguan, China(Mainland) | Cavity Number | Sigly Or Multi Are Accepted |

| High Light | ODM Precision Injection Molding,0.1 mm Precision Injection Molding,ABS Shoe Sole Moulding |

||

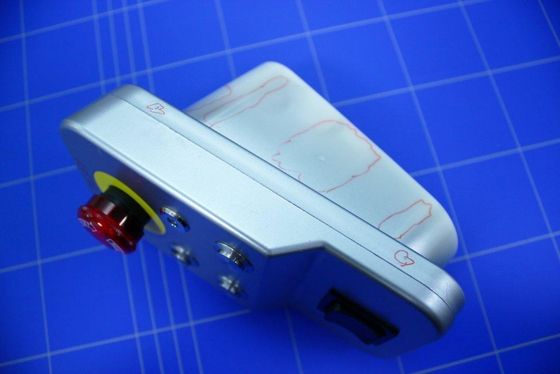

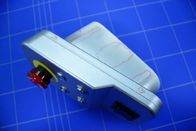

Fabrication ABS / PA / Plastic Shell Precision Injection Molding For Texi Meter

1. Product information:

| Description | OEM Manufacturing Mold Parts |

| Material | 1. Stainless Steel: NAK80,S316,2344 etc. |

| 2. Harden: 48-50HRC | |

| 3. Brass:C36000 (C26800), C37700 (HPb59), C38500(HPb58), C27200(CuZn37), C28000(CuZn40) etc. | |

| 4. Bronze: C51000, C52100, C54400, etc. | |

| 5. Iron: grey iron and ductile iron | |

| 6. Aluminum: 6061, 6063,7075,5052 etc. | |

| 7. And other materials as requested | |

| Finishing | Polishing, Anodize, Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating, Electrophoresis, Delta Seal, Delta Tone |

| Accuracy: | Accuracy Of Machining:+/-0.005mm |

| Accuracy Of Grinding:+/-0.005mm | |

| Surface Roughness:Ra0.8 | |

| Parallelism:+/-0.005mm | |

| Verticality:+/-0.005mm | |

| Concentricity:0.003mm | |

| Application: | Automobiles, Motorcycle, Home Appliance, Electronice Appliance, Sports Equipment and other Mechanical Equipment , etc. |

| Drawing: | JPEG, PDF, CAD, IGS Accepted |

| Payment: | 30%T/T+70%T/T, West Union, etc. |

| OEM service are available. | |

2. Our advantages:

We have the best engineering teams that are from different engineering disciplines. The team members are all young men that are full of passion and experience in mechanical and mechatronic design, product development. Their professional engineering knowledge enables them to provide the best technical supports, to fulfill every need of the customer. Please do not hesitate to contact us if you have any enquiry, we are providing the best service and most competitive price.

![]()

![]()

![]()

Please provide your 2D or 3D drawing with details as below:

1. Type of material

2. Quantity of the product

3. Part application

4. Drawings, samples or pictures with details