-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Shaping Mode | Plastic Injection Mould, Plastic Injection Mould | Mould Base | LKM,HASCO,DME |

|---|---|---|---|

| Design Software | UG,PROE,CAD | Mould Operating Mode | Automatically |

| Product Material | Plastic, ABS,PP,PC | Mould Material | SKD11,NAK80 |

| High Light | SKD11 Precision Injection Molding,NAK80 Precision Injection Molding,PROE Plastic Chair Mould |

||

Outdoor Furniture Custom Injection Molded Plastics Chair Foot For Garden

Quick Details

| Place of Origin: | DongGuang Da Ling Shan .China | Brand Name: | WeiYu Mould | Model Number: | WY-19736 |

| Shaping Mode: | Plastic Injection Mould, Plastic Injection Mould | Product Material: | Plastic, ABS,PP,PC | Product: | Household Product |

| Products Name: | Beer Festival used Outdoor Chair Foot Mold Changed the back of Chair | Design software: | UG,PROE,CAD | Mould base: | LKM,HASCO,DME |

| Mould operating mode: | automatically | Payment Term: | T/T | Package: | wooden case |

![]()

![]()

![]()

Packaging & Delivery

| Packaging Details: | wooden case |

| Delivery Detail: | 65-90days |

Specifications

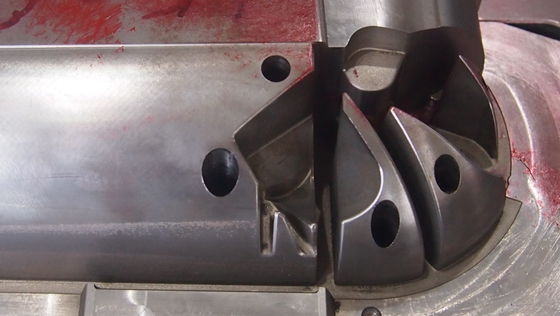

Chair Foot mould

1.Provide 3D design

2.Mould steel/hardness:2738 HRC34-38

3.OEM service

4.mould life:1,000,000 shots

Company Information

Professional in making any kind of household mould for export.

Use import CNC machine to ensure the precision of the mould.

We are professional in making any kind of household moulds, home appliance mould and any kind of injection moulds. Have an experience for more than 16 years.

Any inquiry please contact us.

Product Description

| Product Name |

Chair Foot mould |

| Product material | PP.ABS.PA |

| Core&Cavity Steel | 2738 |

| Steel hardness: | HRC34-38 |

| Mould Standard | DME,etc |

| Cavity Number | Single or multi |

| Injection System | side gate |

| Ejector System | Ejector pin |

| mould base | S50C |

| Cycle Time | 50S |

| Tooling lead time | 60DAYS |

| Mould life | 1,000,000SHOTS |

| Quality assurance | ISO9001 |

| Specification | According to client’s requirements |

| Our Advantage | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the moulds are automotic. | |

| Offer you | In-time response on letters, telephone calls or fax |

| In-time supply the quotation and mould designs | |

| In-time communication on the technical points | |

| In-time sending pictures for the mould machining progress and mould finishing schedule | |

| In-time mould test and sample delivery | |

| In-time mould delivery. | |

|

garden chair foot mould |

|

| 1.Samples/Drawing &Requirement from you | |

| 2.Mould design:we will Communicate&Exchange the opinion with you after you place order. | |

| 3.Material Purchase:Steel cutting and Mould base tooling. | |

| 4.Assembling. | |

| 5.Inspection of mould : following and controlling the tooling processing. | |

| 6.Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you! | |