-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

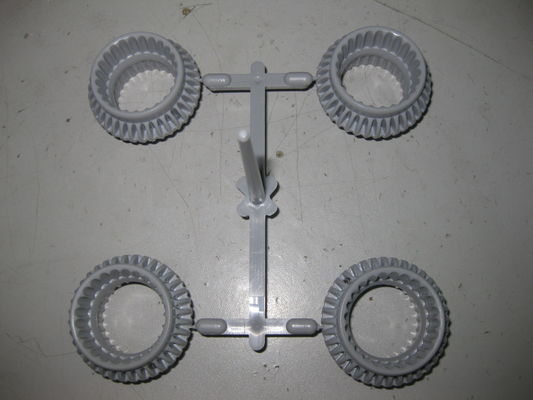

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Certification | FDA,ISO13485 | Cavity | Multi Cavity |

|---|---|---|---|

| Mold Material | H13,50#,P20 | Design Software | CAD/ProE/UG/SOLIDWORKS |

| Application | Industrial | ||

| High Light | PE Commodity Mould,P20 Commodity Mould,ABS multi injection molding |

||

ABS / PP / PE Plastic Injection Mold , Electronics Parts Nokia Protective Case

Item: Mold/Plastic Mould /Plastic moulding /for car part/Injection plastic mold/Plastic Injection Mould /mould maker/printer mould Specifications.

| 1. Plastic mould making according to Sample or 3D Drawing |

| 2. Design or Manufacture |

| 3. Strict quality control for customer |

| 4. Fast delivery with low cost |

Mould making sheet

|

Name |

plastic injection mould,plastic mould,injection mould,plastic injection tooling ,prototype,injection plastic mould |

|

mould material |

45#,P20,H13,718,2738,NAK80,S136. |

|

mould base |

LKM,HASCO |

|

Cavity |

1 or more |

|

Runner |

cold or hot runner |

|

Mould life |

45# :300,000-500,000shots |

|

P20: 500,000shots |

|

|

718: 700,000shots |

|

|

Design software |

UG,PROE,CADetc. |

|

Plastic material |

PP,PE,ABS,PC PET pa66 . |

|

Delivery time |

25days |

|

Specification |

with good quality lower price |

Mould making

1. Samples/Drawing &Requirement from you

2. Mould design:we will Communicate and Exchange the opinion with you after you place order.

3. Material Purchase:Steel cutting and Mould base tooling.

4. Assembling.

5. Inspection of mould : following and controlling the tooling processing.

6. Mould testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7. Your instruction &confirmation for shipment.

8. Ready made mould before packing.

Following is also the essential informations, for customer reference

|

1. Ready step |

customer suppy us 3d drawing or sample .we make the injection mould drawing |

|

|

|

|

2. Negotiation |

the quality, price, material, delivery time, payment item, |

|

|

|

|

3. Place an order |

according to the confirmed plastc injetion mould drawing |

|

|

|

|

4. Mould |

According to customers request to build the injection mould. Before make the mould, we send mould design to customer approval first, and cusotmer pay the deposit ..before move forward to production; we will send samples to customer to confirm first. |

|

|

|

|

5. Sample shoot |

If the first sample come out is not satisfied customer, we will modify the mould till meet customers satisfactory. |

|

|

|

|

6. Products in store |

If your quantity is beyond our storage, we will provide lead time to you. |

|

|

|

|

7. Delivery time |

Delivery goods by sea or by air, according to customers requirement. |

INJECTION PLASTIC MOULD

1. Quality assurance: ISO 9001:2000

2. Material: TPU;ABS; PP; PE; HIPS; PC; POM; PA6; PA66; PBT and so on for option.

3. Average processing quantities: 10000 pieces per day

4. Mold Type: Injection Mold

5. Die-set Type: LKM Standard

6. Mold Core Material: S136, H13, 2344, 718, 738, 8407, NAK80 etc

7. Mold Cavities: design

8. Mold Making Time: 25 days