-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Certification | FDA,ISO13485 | Product Name | High Quality Virgin Raw Material Custom Plastic Injection Mold Product |

|---|---|---|---|

| Runner | Hot Runner\ Cold Runner | Cavity | As Per Client's Requirement |

| Mold Material | 50#,P20 | Design Software | CAD/ProE/UG/SOLIDWORKS |

| Application | Automotive | Mold Life | 500000 Shots |

| High Light | FDA Air Conditioner Mold,2344 Air Conditioner Mold,PVC Plastic Moulding 500000 Shots |

||

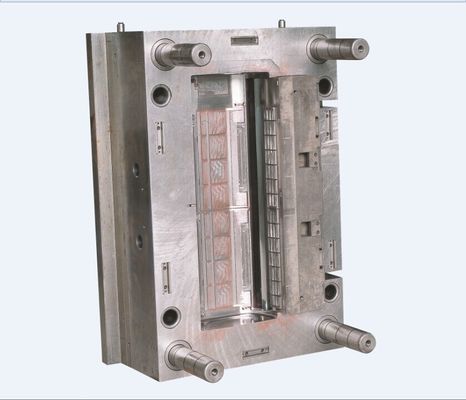

Hot Sale Plastic Mold For Air Conditioner Mold / Home Appliance Air Condition Cover Injection Moulds

Packaging & Delivery

| Packaging Detail: | -Painting Grease On Mold Surface With Plasic Pellicle Or PE Bag & Disinjected Wooden Case (Base On Client Require) -2D &3D Drawing, Dimension Report,Spare Part, TF Samples Together With Mold Shipment. |

| Delivery Detail: | 4-5 Weeks For Mould Build Or Base On Clients Require |

Specifications

Air Conditioner Mould Professional Plastic Injection MouldLower Cost & 20 Years Experience

Prompt Delivery

Longe

Capable of handling a complete program management and Mold matching based on final parts assembly specifications

Type Of Mould

Single / Multi-cavitation Molds

Precision Molds

Insert Molds

Steam High Glossy Molds

Die Casting Molds(Tool Build And Molding)

Dual color (two color) injection Molds

Gas- assisted Molds

Using various type of auxiliary accessories such as Hot- runner system, insert molding

|

Tool Build Standard |

HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

|

Mould Base |

LKM&Hasco&DME standard (A,B plate 1730,2311 ,2312,P20 ) |

|

Core & Cavity Steel |

Nixman,DIN2312,2738,2344,718,738H,S136,8407 ,NAK80,CENA1,SKD61,H13 |

|

Steel Hardness |

46~56HRC |

|

Material for Slider ,Lifter and all sub insert |

1.2767 HRC |

|

Cavity No. |

Single-cavity ,Multi-cavity |

|

A surface request: |

EDM & Texture,Sandblast,Polishing,High Glossy |

|

Gate |

Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

|

Maximum mould size |

1600*2600 mm |

|

Mould life time |

500000~+1,000,000 shots |

|

Quality |

TS 16949; ISO 9001:2008:ISO 9001:2000 certification |

|

Product material |

PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC, HDPE(High Glossy Material) etc |

|

Lead time |

4~7 Weeks Or As Per Client Require |

|

Package |

Painted Mold Surface/ Disinjected Wooden/Plywood case/PE bags/Export Carton For Parts |

|

Payment terms |

T/T,L/C,D/P,D/A, |

|

Trade terms |

FOB Shenzhen,Hongkong ,EXW ,CIF |

|

Export country |

Europe countries,USA,Mexico,Australia ,Middle-east,Turkey ,Asia etc |

|

Value-added service |

Polish,Texture,Painting,Moulding,Turnkey project,Plastic Part Production |

Painting Grease On Mold Surface With Plasic Pellicle Or PE Bag & Disinjected Wooden Case (Base On Client Require)

2D &3D Drawing, Dimension Report,Spare Part, TF Samples Together With Mold Shipment.