-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

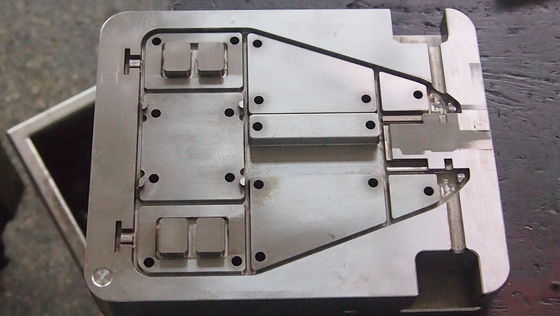

| Design Software | CAD, PROE . UG.CAM .etc | Cavity Number | Sigle Or Multi Are Accepted |

|---|---|---|---|

| Product | Vehicle Mould | Gate | Pin Point Gate ,edge Gate |

| Finish | Semi-matt .polish | Second Processing | Silk-screen Printing ,plating , Painting |

| High Light | PA66 OEM Injection Mold,PROE CAD Injection Plastic Mold,S136 Injection Plastic Mold |

||

PA66 / PA OEM Trade Assurance Customized Injection Plastic mold

Specifications

plastic injection molding service

1.Single or mutil cavity

2.Hot or cold runner

3.PROE UG and CAD design

1 . Mould specifications

Material of steel

cavity and core use imported S136 stainless steel with fine polishing, high hardness to get mold's high precision and good quality.

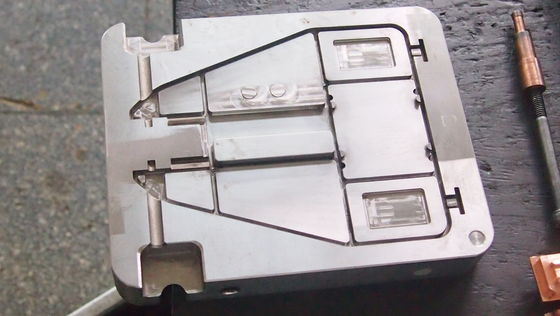

About gate

pin-valve gate ,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

About hot runner

hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production ,cavity with lower injection pressure to reduce wear and tear of mould parts.

Heat system

with double heating system,it has separate temperature control mode ,the heat bar are used to heat the mould mainfold plate,small heaters supply the heating temperature for cavity nozzle continuously.

Cooling system

each parts including core ,cavity and valve gate has independently cooling system.