-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Color | Optional | Software | CAD,PRO-E,UG.ETC |

|---|---|---|---|

| Runner | Hot Runner / Cold Runner | Usage | Custom Molds Make |

| Part Surface | Painting,chrome,silk Sreen | Mold Steel | NAK80. S136. 2343. 2344.SKD61 |

| Highlight | 2343 Low Cost Plastic Injection Molding,2344 Low Cost Plastic Injection Molding,S136 plastic injection mold tooling |

||

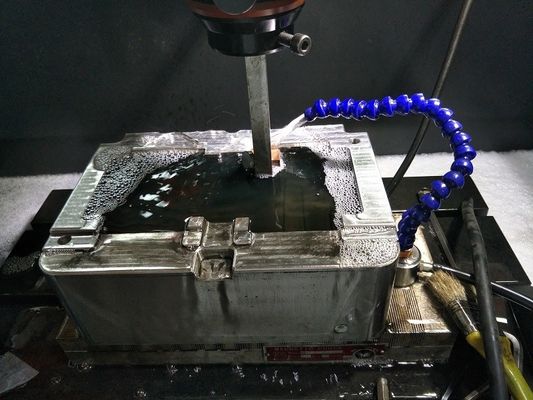

PP / POM / PA Black Color Plastic Injection Mold For Making Protective Cover For High-tension Busbar

Precision Mold design and making FACTORY

1. Product description

| Name | High precision stamping die mould design and make in China |

| Mould material | SKD11, ASP-23,SKH9, SKD61,P20,NAK80,8402,8407 etc. |

| Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

|

Material main core and Cavity insert |

DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13; |

| Cavity | Single / Multi per request |

| Runner | Hot / Cold |

| Mould life | 300,000-500,0000shots |

| Maximum mould size | 1500*1500 mm |

| surface request | EDM & High Polish |

| Design software | UG,PROE,CAD etc. |

| Plastic material | PP,PC,PE,ABS,PVC etc. |

| metal products | Electronic: Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards,USB housing. Automotive interior parts: connector, navigation frame, car key. All kinds of connectors, digital parts,watch cover,mobile cover. |

| Lead time | 10-60days |

| Specification | Depends on customer’s requirements |

| Payment terms | T/T, L/C,Paypal, Western Union |

| Trade terms | FOB SHENZHEN |

| MOQ | 1 set |

| Injection machine type | High speed machine,80T,120T,150T,200T,250T,350T,500T,800T |

| Package |

Wooden/Plywood case for tool ,PE bags add export carton for parts |

| Value-added service | Polish,texture,painting,screen printing,turnkey project |

![]()

![]()

![]()

![]()

![]()

![]() APPLICANCE

APPLICANCE

As an experienced mold manufacturer,

Our products mainly apply for the following areas:

Automobile: Auto interior plastic case, Auto lamp, Instrument panel, plastic auto connectors.

Electronic: Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards,USB housing, Mobile phone plastic part, remote control, key-press;

Mechanical: Junction box, Motor support plastic part, Pump plastic part, mower plastic parts;

Household: Fashion cup, Juice cup, 5 Gallon bottle cap, bottle with screw cap, safety helmet plastic parts;

Medical: Medical instrument body plastic parts, hearing aids,Hollow fiber Dialyzer, Blood-Pressure meter,Stapler;

CNC Machining: various aluminum products, CNC machining;CNC turning;CNC milling;CNC cutting;

Stamping parts: Stamping die connectors, metal stamping parts, terminals, pins,

shielding case, lead frames, small hardware products.

Mould spare parts: High precision mold core.