-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Design Software | CAD, PRO-E, UG, Solidworks, Catia | Product Material | PP,PE,PC,PS,ABS,PA66,TPE,etc |

|---|---|---|---|

| Core&Cavity Steel | P20,718, 2738, 2316 ,S136,SKD61,NAK80,etc | Quality Assurance | ISO9001 |

| Mould Life | 1 Million Shots | Ejector System | Ejector Plate |

| High Light | ABS Injection Mold,CAD ABS Injection Mold,NAK80 injection mould plastic |

||

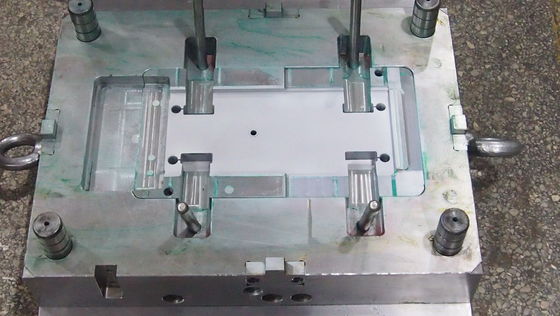

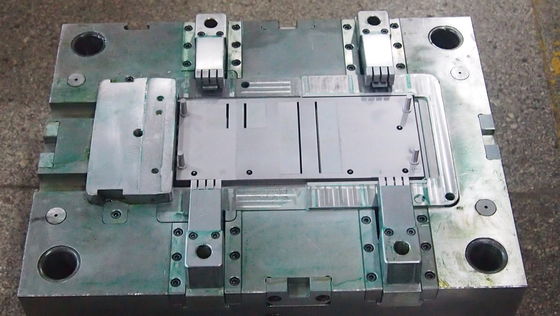

PC / ABS / Injection Mold Mould For Electrical Remote Control Injection Part

Specifications

Plastic Mould

1. Plastic mould steel:2343 HRC48-50 Degree,P20,2738,718.NAK80.2316.

2. Plastic mould cavity:single/multi

3. Plastic mould design software:UG,CAD

Weiyu plastic Mould Factory is a leading plastic mould manufacture in Chain.Have more than 20 years experience to produce plastic molds for injection molding .We produce automobile parts mold ,plastic chair mold ,table mold ,bucket molds,turnover box molds and other more plastic injection molds.We adopt CAD/CAM/CAE to design all the mould combine our advanced technologe machine equipment and strict quality management to produce.

| Design Software | CAD, PRO-E, UG, Solidworks, catia |

| Product material | PP,PE,PC,PS,ABS,PA66,TPE,etc. |

| Core&Cavity Steel | P20,718,2738,2316,2311,S136,SKD61,NAK80,etc |

| Steel hardness: | HRC34-52 |

| Mould Standard | DME |

| Cavity Number | Single/multi |

| Injection System | 8 points of hot runner system |

| Ejector System | Ejector plate |

| Cycle Time | 30s |

| Tooling lead time | 50 days |

| Mould life | 1 million shots |

| Quality assurance | ISO9001 |

| Equipments | High speed milling center |

| Milling center | |

| Numerical controlled EMD machine | |

| High speed EMD drilling machine | |

| Mirror EMD machine | |

| Quick wire cutting machine | |

| Slow wire cutting machine | |

| COMERO | |

| Large grinding machine | |

| Precise grinding machine | |

|

Process

|

Quote competitive price according customer detail requirement. |

| Sign agreement | |

| Customer T/T deposit to us to start to design mould | |

| Send mould drawing to customer for confirmation | |

| Mould design confirmed and start to make mould | |

| Make mould trial during tooling time (Which we get agreement with customer) | |

|

Send mould trial sample to customer for inspection. Or customer come to our factory to inspect mould personally |

|

| Customer T/T balance to us after mould confirmed | |

| Deliver mould after get balance. | |