-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

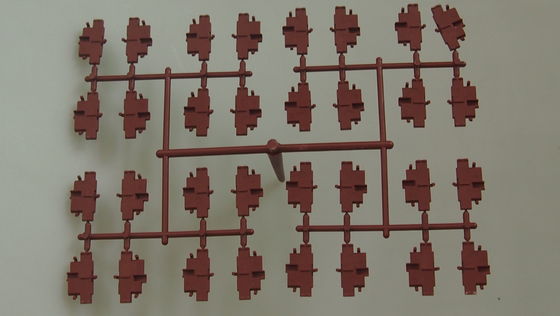

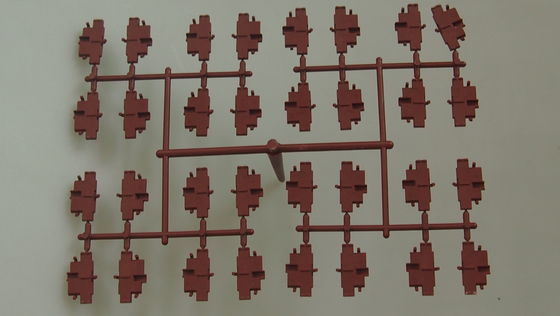

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Size | Customized Size | Cavity | 32 Cavities |

|---|---|---|---|

| Steel | 2343 HRC 48~50 Degree | Mould Base | LKM |

| Material | PA66/ABS+PC/PC | Mold Style | Injection Mold |

| High Light | PA66 Medical Device Plastic Injection Molding,ABS Medical Device Plastic Injection Molding,32 cavities double color injection molding |

||

PE / ABS / PP / PA66 Plastic Injection Mold , Double Color Injection Molds

Specifications:

Material: NAK80, S136, P20 SO ON, ABS PE PC PVC

Standard: HASCO,STACK,DME,PCS..

delivery time :30days

ISO9001:2000 OEM&ODM

Why choose us?:

1. More than 30-years experience.

2. ISO9001:2000 certificated.

3. Competitive price with high quality.

4. More than 50 machines support to run the business.

5. Custom R&D program coordination.

6. Expert technicians.

8. Diligent and loyal workforce.

9. Up-to-date software.

10. International standards, SAY, HASCO, DME, MISUMI, etc

11. Well-rounded after service.

Important Note:

1. The injection mould is customized for our clients.

2. We do not sell ready-made injection mould, but custom injection mould. So, no price list available.

3. Quotation available after discussion on requirements and design.

What’s our Injection Mould experiences?:

1. Multiple cavities Injection Mould

2. Insert Injection Mould

3. Multiple slider action Injection Mould

4. Sandwich Injection Mould

5. Hot runner system

6. Injection Mould with international standard, like HASCO,DME etc.

7. Other custom Injection Mould

How To Custom My Own Injection Mould?

| STEP | DETAIL |

| 1.Enquire /Quote | Discuss with customer after received buyer’s samples or drawings. |

| 2.Negotiation | Quality,Technique requests,Mould material,Price,Delivery time,Payment,etc. |

| 3.Place order | Sales contract + proforma invoice. |

| 4.prepaid | Customer T/T deposit to us to start to design mould. |

| 5.Mould design | We will communicate&exchange the opinion with customers during making drawing according to the sample. |

| 6.Design confirmation | Send mould drawing to customer for confirmation. |

| 7.Mould processing | Start to manufacture, we will sent photos to show tooling process. |

| 8.Sample confirm | Send the sample or as negotiation. |

| 9.Mass production | If customers need mass production plastic products, We can also offer. |

Description :

| Mould Base | LKM,HASCO,DME |

| Cavity/core material | 2738,2343,S130,2344,718,8407,S136,P20,KD-61,NAK80,H13 ect |

| Cavity QTY | Single-cavity/Muti-cavity |

| Runner | cold/hot runner |

| Gate | Submarie gate,side/edge gate |

| Mould lifetime | 500,000 shots |

| Plastic part material | PC,PA,ABS,PVC,PA66,TPE,SAN,POM.etc |

| Lead time | 20-40days based on different products |

| Package | Wooden cases or cartons |

| Port | ShenZhen |

| Design sofeware | UG/CAD/PROE |