All Products

-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

Contact Person :

wang

Phone Number :

13922546862

WhatsApp :

+8613922546862

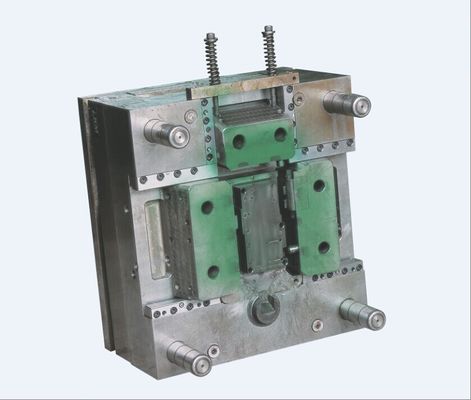

Zinc Alloy Custom Made Die Casting Molding Mutli Cavities OEM ADC12

Product Details

| Shaping Mode | Punching Mold,Compression Mould | Product | Household Product |

|---|---|---|---|

| Surface Treatment | Sand Blasting | Dimensions | ADC12 |

| Mould Material | SKD11,s316,718 | Color | Customized,Black |

| Lead Time | 45 Days | ||

| High Light | Mutli Cavities Die Casting Molding,OEM Die Casting Molding,ADC12 custom made molding |

||

Product Description

Aluminium / Zinc / Zinc Alloy Die Casting Molding With OEM Service

Packaging & Delivery

| Packaging Detail: | free check wooden box |

| Delivery Detail: | 30-50 days, or according to your request |

Specifications

Aluminum die casting mould

1. OEM&ODM offer your sample or 3D drawing

2. material: H13,2344,8407,SK61

3. Mutli-cavities

Die casting part:

OEM manufacturer for die casting parts and die casting mould.

1 . High precision die casting parts in Zinc or aluminium alloy.

2 . Customer's drawing or sample will be highly followed up. the drawing in stp or igs format will be helpful.

3 . Surface:Zinc plate,Chrome plate,Trivalent chrome plate,Powder coating,Painting,E-Coating.Phosphating,Dying....etc.

4 . Flexible cooperation term,small orders for testing is acceptable.

5 . Green product with different international approval.

6 . High quality with reasonable price.

7 . Poly bag+carton with separator for die casting parts,color box design is acceptable.

8 . Different size,different material,different finishing are availabe according to your request.

Die casting molds:

1 . ISO9001:2000 Cerficate

2 . In line with European standard

3 . Mould life: Over 800 thousand,lifetime free for maintaining the mould.

4 . Die casting Machine: 88T,160T,180T,200T,280T,400T.can meet your different part size.

Aluminium die-casting process:

Drawing design or sample(from clients)---The prototype produced (CNC prototype machining)---Customer confirmation---Mold design and manufacturing---Trial run---Customer confirmation---Mass production---Remove burr---polishing---hole drilling---Tapping(thread)---Finishing(according to product requirements)---QC/QA---packaging---shipping

If you are looking for a die casting supplier with good quality,competitive price and efficient service.

Pls stop here,try to work with us.We promised you can get the best offer here. Thanks.

Recommended Products