-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

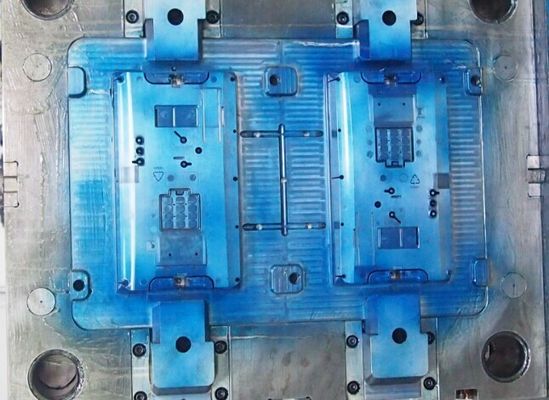

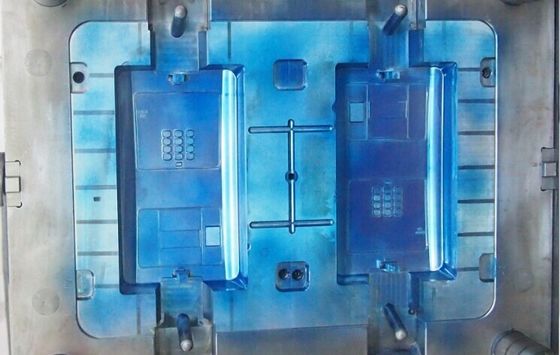

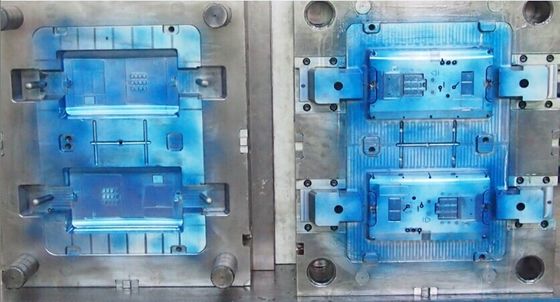

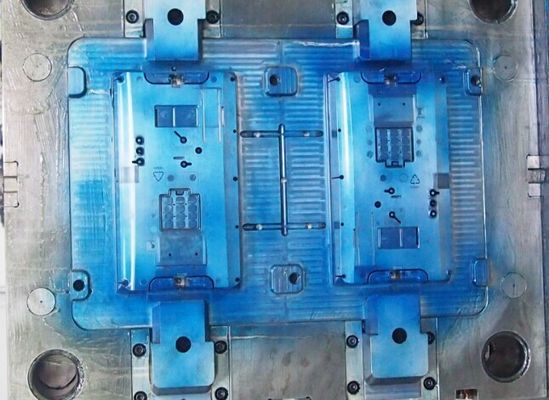

| Shaping Mode | Plastic Injection Mold | Mold Base | LKM |

|---|---|---|---|

| Mold Standard | DME/HASCO | Design Sofware | AUTO CAD,UG.PRE |

| Muld Life | 250000~1000000 Shots | Surface Treatment | Mirror Polish |

| Highlight | Overmolding Insert Injection Molding,LKM Insert Injection Molding,DME metal insert molding |

||

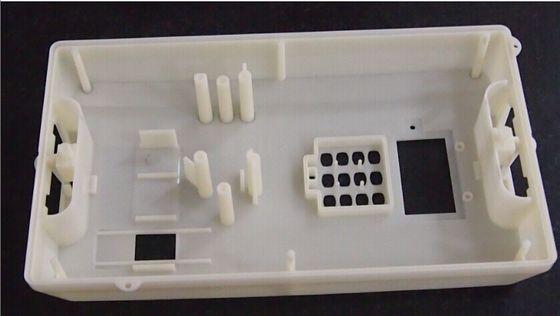

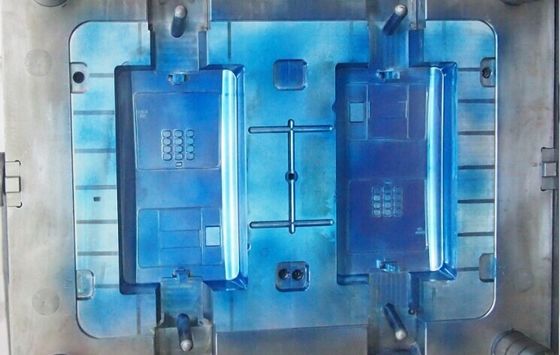

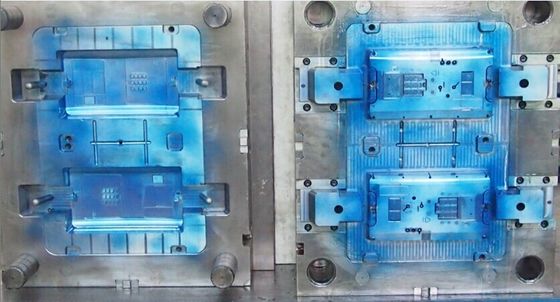

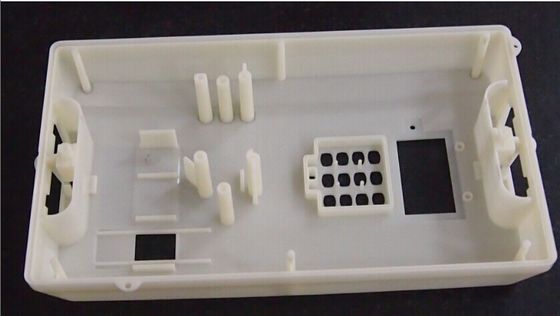

Custom Metal Insert Mold, PE / ABS / PVC Engineered Component Molding

1 . Custom Metal Insert Mold, PE / ABS / PVC Engineered Component Molding

2 . Plastic material: PP/PE/ABS/HDPE/PVC/PMMA etc.

3 . Multi Cavity

4 . Hot runner

5 . OEM & ODM service

1. name | High Quality metal inserting overmould Mould |

2. plastic material | PP/PE/ABS/HDPE/PVC/PMMA etc. |

3. mould material | P20 |

4. life | 400,000shots |

5. cavity | multi |

6. runner | hot |

7. mould weight | 56kg |

8. mould size | 500mm*450mm*300mm |

9. mould base | 45# |

10. molding cycle | 15 second |

11. accessories of mold | LKM |

12. design software | UG, Pr/E, Solid works,CAD |

13. suitable mould machine | 320T |

14. MOQ | 1 set |

15. payment | 40% as deposit by L/C,and 60% as the balance by T/T |

16. package | wooden case |

17. delivery time | in 45 days |

18. OEM or ODM | is available |

19. logo | welcome to design |

20. after-sales service | one year is warrantied |

Applications:

This is the high precise and quality mould which is won the wide reputation in USA and EU market, HASCO standard. The metal parts can be inserted into the mould cave and overmoulded.

Specifications:

Model No.: pm-051

Item: plastic mold

Multi-Material Molding

OEM & ODM service

Competitive Advantage:

1 . 15 Years OEM and ODM experience in plastic injection molding service for Electrical parts, Medical treatments, Bathroom plastic accessories, Telecommunication devices, Toys and Crafts: One stop tooling room and injection center.

2 . Advanced equipment and professional technology: CNC, CMM and injection machines from 80MT-1200MT.

3 . Advanced R&D service and Best Engineer: DFM and Mold Flow Analysis.

4 . Excellent and Nice IML (In Mold Labeling) technology, we can put labels on 4 sides in the mold together when injection.

5 . Quality and Price: Quality-oriented and cost drivers analysis to share cost reduction with customers.

6 . Series service of design, prototyping, paiting, printing and assembly( 3 assembly lines for finished products)