-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

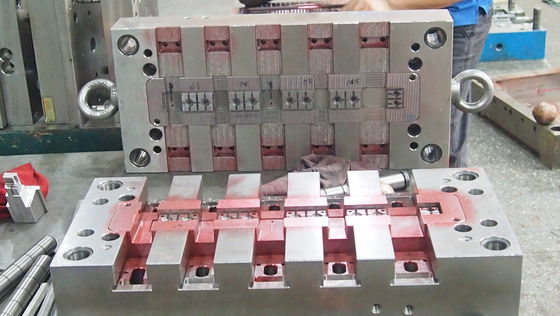

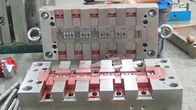

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Mould Base | LKM,HASCO | Runner | Hot Runner\ Cold Runner |

|---|---|---|---|

| Mould Life | 250000-300000shots | Surface Treatment | Polish. Etched. Texture |

| Size | According To Your Drawing | Material | PEEK,ABS |

| Mold Base | LKM,HASCO | ||

| High Light | PA66 Electric Injection Molding,K7 Electric Injection Molding,Custom Molded Plastics 300000shots |

||

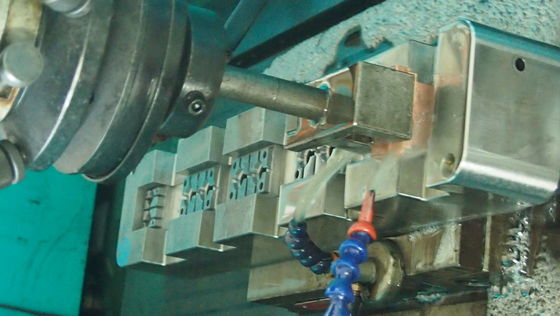

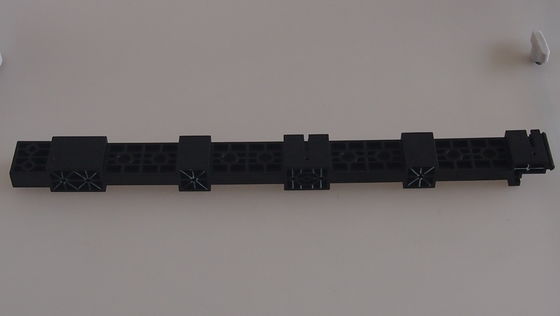

PA66 High precise Plastic Electrical Support Bar Mold Plastic Injection Mould

Quick Details

· Place of Origin: Guangdong, China (Mainland)

· Brand Name: OEM

· Model Number: SZRJC

· Shaping Mode: Plastic Injection Mould

· Product Material: Plastic

· Product: Plastic Mould for auto parts

· Mold: Auto Parts Mould

· Product Material:ABS,PP,PC,PA,PMMA,PS,POM and etc.

· Mould material: 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc

· Moldbase: FUTABA,LKM,HASCO,DME

· Plastic cavity: Multi or single cavity

· Mold runner: Both of Hot&Cold runner you can choose

· Gate type: Side gate,Sub gate,Pin point gate,Edge gate etc

· Mould life: 200~1000M available

· Certification: ISO 9001:2008

· Delivery: By DHL,FEDEX,Shipping.

· Packaging and Delievery

| Packaging Details: | Products packaging: 1,With plastic bag,with pearl-cotton package. 2,To be packed in cartons. 3,Use glues tape to seal cartons. 4,Deliver out by DHL,FEDEX. Or according to customers' requirement. Moulds packaging: Standard wooden case,and pallet, suitable for shipment, to avoid damaging,or according to customer's requirement |

| Delivery Detail: |

15 to 25 days for building production mould

|

| Product type: | Professional custom plastic injection moulding/injection plastic mould manufacturer |

| Our advantages: | 1,Competitive price with high quality 2,Short lead time 3,A variety of professinal equipments 4,Efficient team and experienced engineers 5,One-stop solution from design to mould manufacture and mass production |

| Product material: | ABS,POM,PC,PA66,PVC,PVE,PMMA,PA+GF,PBT,PET,PU,PP,Rubber |

| Mould base: | FUTABA,LKM,HASCO,DME all available |

| Runner: | Cold/Hot runner |

| Cavity: | Single or multi cavity |

| Standard parts: | HASCO |

| Gate type: | Side gate,Sub gate,Pin point gate,Edge gate,etc |

| Treatment: | Heat treatment, Nitriding, Polishing, etc |

| Hardness: | HRC 45-52 |

|

The standard appearance of the products for stripe: |

MT(mold tech),YS,HN series |

| Color contrast way: | RAL K7, PANTONE |

| Payment: | T/T 50% deposit in advance,balance before shipment |