-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

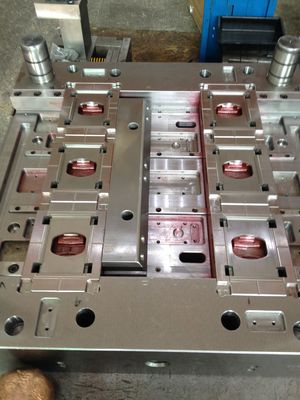

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

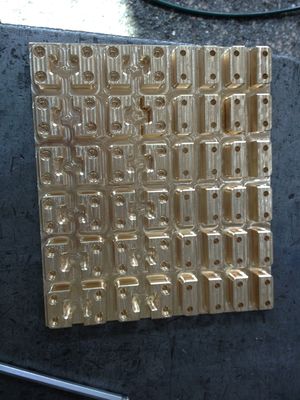

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Product | Vehicle/Medical Equipment/automobile Industry Mold | Cavity | Single/Multi |

|---|---|---|---|

| Runner | Hot Runner\ Cold Runner | Mould Life | 250000-300000shots |

| Mould Base | Non-Standard | Name | 3C Products Mould |

| Material | Plastics | ||

| High Light | Hot Runner Injection Mould 300000shots,3C Hot Runner Injection Mould,32 Cavities 2 plate injection mold |

||

32 Cavities Hot Runner Injection Mould Plastic Cap Mould ABS / PC / PA / POM / PP

We can supply: mineral water cap mould, beverage cap mould, 5gallon cap mould, theft proof cap mould, shampoo cap mould, different kinds of oil cap mould, sport cap mould, cosmetics cap mould, wine cap mould.

SERVICE

1. More than 10 years experience in PET Preform Mould.

2 . Devote to professional packaging solutions for beverage,daily chemail, medicine.

MOULD FEATURES

1 . Core,Cavity and Neck can be interchanged.

2 . Excellent hot runner system and cooling system.

3 . High quality materials and proven mold design ensure long life time

4 . Pneumatic Pin Valve strcuture without manual cut tail,reduce the labor force.

5 . Double self-lock structure ensures mold thickness tolerance less than 0.1mm

HOT RUNNER SYSTEM

1 . Less energy cost and pressure lost.

2 . Use imported heaters,like Germany HOTSET and Italy ROTFIL.

3 . Cavity-to-cavity control system ensure nozzle temperature fluctuates within 1oC

4 . Hot Runner Balance design ensures evenly force,uniform heating and identical preforms.

COOLING SYSTEM

1 . Sprial Water Cooling Way on cavity enhances cooling performance.

2 . Cooling System on neck and move neck plates enhance cooling performance.

3 . Precise Distributary Plate distributes cooling water into cavity evenly,quicken preform cooling.

mould business processing:

1 . clients provide us sample or 3d drawing

2 . after receive ,confirm the details requirements like:cavities,runner,price,lead time,payment terms

3 . confirm the order

4 . provide the 3d drawing to clients for check before production

5 . before delivery one week,send the test sample to clients for check

6 . if clients not satisfary,we will fix mould until satisfary

7 . after receive the balance fee,packaged,and arrange to port