-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

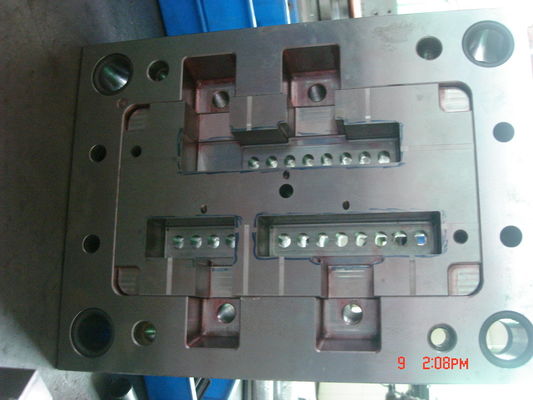

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Sprue Gate | YUDO Runner ,Hot Runner,Cold Runner ,Pin -point Gate,Submarine Gate,etc | Mould Cavity | Singe Or Multias Your Requirement |

|---|---|---|---|

| Mold Shaping | Plastic Injection Mold | De-mold Type | Automimatic Eject |

| Mold Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#45#etc | ||

| High Light | S136 Automotive Plastic Moulding,LKM Automotive Plastic Moulding,NAK80 Auto Parts Mould |

||

ABS / PP / PE Household Molds , Auto Parts With NAK80 Core , LKM Base

Product Description

| Packaging Details: | For mold: After assemble and clear mold, we paint anti-rust fog or grease on mold, then cover it with thin film and place it into a stable wooden box. For plastic product: the first thing is to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into cartons with thin sponge plates to prevent scratches. Or as per your request. |

| Delivery Detail: | 10 days |

| ABS plastic product injection mold making for remote control cases | |

| Mold Name | China molds product |

| Mold Shaping | Plastic injection mold |

| De-mold Type | Automimatic Eject |

| Mold Base | LKM & Hasco & DME |

| Mold Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#45#etc |

| Mould Cavity | Singe or multias your requirement |

| Sprue Gate | YUDO runner ,Hot runner,Cold runner ,Pin -point gate,Submarine gate,etc |

| Design Software | UG,PROE,CAD,CAXA,etc |

| Plastic Material | PP,PC,PS,PAG,POM,PE,PU,PVC,ABS,PMMA,etc |

| Moild Life | 300000-1000000 shots |

| Delivery Time | 15-30 days |

| Payment Terms | T/T , Paypal |

| Packaging | Wooden Cases |

| Transportation | By sea or by air as your requirement |

| Expor Country | worldwide |

| Specification | As your requirement |

| OEM /ODM Order |

welcome

|

Our Services

rapid prototyping,bending ,CNC maching,punching mould,silicicone,moldingInjection mould,die casting mould,metal , plastic prototyping, sheet stamped parts, insert/over molds,multi-cavities mould, rubber injection mould,etc.

Product range: high quality electronic product, automotive components, medical device, home appliance, etc.

Advantages:

1 . Mold design is subject to customer's requirement.

2 . Injection molding machine specification of certain plastic,etc.Our products include a variety of vacuum cleaners,and plastic components.

These products are widely available to world-class large companies.

We have won a high reputation among clients.Our company provides processing or researching and manufacturing services.

We are very interested in the development of new products to meet market demands.

3 . specifications about flow,material,radian and so on,we can fit in all you want.

Company Information

Weiyu has founded in 2006, has evolved to be one of the leading customer injection molders of our region.

2 . Weiyu engaged in the development, design and manufacture of precise plastic mould and plastic parts, and specialize in offering all-around service for customers such as the design and fabricating of tooling, injection and painting.

3 . Weiyu is including R&D center, tooling, moulding, silkscreen, spraying workshops and assembley line.

Producing capability:

We have a excellent team of specialists and undergratuates and advanced engineers. R&D department , , and 50 engineers, the department of mould manufacturing, 120 professional mould makers.

Supplier Advantages:

1. Can supply with both Mold & Molded parts

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services

3. With more than 22 years experience, all of works are done 100% in our factory in DongGuan.

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples

Packaging & Shipping

For mold: After assemble and clear mold, we paint anti-rust fog or grease on mold, then cover it with thin film and place it into a stable wooden box.

For plastic product: the first thing is to wrap each part up with semi-transparent thin foam and put it into plastic bag, the second step is place them into cartons with thin sponge plates to prevent scratches. Or as per your request.