-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Product Name | Plastic Injection Mould | Runner | Hot Runner\ Cold Runner |

|---|---|---|---|

| Design Software | CAD/ProE/UG/SOLIDWORKS | Mould Material | P20/718/738/NAK80/S136 |

| Application | Automotive | Mould Base | Non-Standard Plastic Injection Mould |

| High Light | NAK80 home injection molding,S136 home injection molding,Solidworks Toy injection molding |

||

Toys and Crafts Commodity injection Mould Hot Runner / Custom Injection Mold

Plastic mold

|

Parts Material

|

Plastic injection molding grade, such as PE, PVC ABS, PC, PP, POM, PA6( PA66, GF filled), PMMA, PET(PBT) |

|

Cav.& Cor. Material |

P20, H13,S136, NAK80, 718, 2738, 2316, SKD61 etc; |

|

Mold Base |

LKM, DME, HASCO or Customize according to customers' requirements; |

|

Cavity quantity |

1*1, 1+1, 1*2, 1+1+1, etc. |

|

Shot Runner |

Cold or Hot Runner_ HASCO/DME/YUDO etc. |

|

Mold lifetime |

100K to 1500k shots or according to customers quantity condition to decide it with saving cost for our customers. |

|

Soft wares |

CAD/CAM/CAE, UG, Pro/E, Powmill, Solid works etc. |

|

Package |

Wooden box with steel frame packing or OEM packing |

Plastic Mold (Moulds) production process

|

1. OEM Service |

OEM & ODM service, we can provide design service if needed |

|

2. Quotation |

Including the price of moulds, moulds sizes, material for cores & cavities, weight of moulds, freights for moulds & parts (if needed), part cost, moulds lifetime, delivery, etc. |

|

3. Purchasing Order |

As per the customers' designs of parts, and suppliers accept the orders |

|

4. Confirmation |

Provide moulds drawings to customers for confirmation, after that, order moulds base & material, start production |

|

5. Component |

High speed chip makes the reflection more quickly |

|

6. sample shoot |

provide the moulds test samples for confirmation, after that, mass production |

|

7. Delivery |

deliver goods by air or by sea, as per the requirements of customers |

|

8. Package |

Wooden case for moulds, cartons for parts |

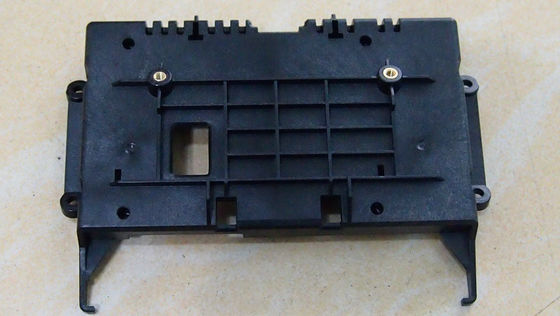

Tool Description: plastic injection mould,cold runner

Material of product:ABS

Cavity quatity:2

Mould design by:WEIYU PLASTIC MOLD PRODUCT CO.

Mould base:50#(steel)

Core and cavity material:S136(420)

Push out:by pin

Gate:pin point gate

Surface finish:polishing,veins

Mould life:500,000 shots

Plastic injection mould for ABS product pp cover,pp case for electric component

Mould make description

OEM/ODM following clients request

Manufacture flow

1 . Client provide 3D drawing informat of STP,IGS,PRT or solidworks and other detailed information for the plastic products

2 . send the quote in time

3 . well design the 3D drawing after the client place order,and start to make mould after confirming by customer

4 . well send the traial mould before dellievring

5 . Delievering the mould

ABOUT US:

DongGuan WeiYu Plastic Mold Co., Ltd. specializes in producing mould & plastic products. We are professional in manufacturing different kinds of plastic moulds,and relative plastic products. We have won high reputation among clients in the fields of consumer electronics, Communication Equipments, and other emerging product field.

We hold "quality is life, customer is God" as our service aim, and provide our customers with high quality products and competitive price. We ensure the shortest delivery time and honest cooperative attitude in order to pursue product quality and customers' trust.

Our company can be generally divided into mould production department & injection moulding department.The machines we use to produce moulds are mainly introduced from Taiwan (original CNC Milling Machines, EDM, Millers, drill machines, and grinders) and the equipments used in injection moulds are imported from Japan (Toshiba and Nissei Plastic injection machines). We own professional engineers and workers who can satisfy your needs of quality and service. We provide mould design, development, and production services. The advanced equipment and skillful workmanship provide the best guarantee for our product quality. We will always focus on customers' needs and expectation and product quality.

Our modes of business operation are various. Processing as per clients' orders, processing with clients' supplied sample/sketches, and researching & developing products together according to customers' requirements are all available.

We sincerely hope that we can cooperate with you.