-

Automotive Injection Molding

-

Precision Injection Molding

-

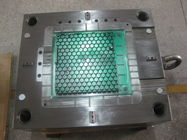

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Mold Surface | Texture ,high Gloss Polishing . | Mould Standard | DME/HASCO |

|---|---|---|---|

| Parts Material | ABS/PP/PE/PC/PEEK/PVDF | Mold Material | 738/718/P20/2344/2343/NAK80/8407/SKD61 |

| Runner | Hot / Cold Runner | Mold Base | LKM |

| High Light | ABS Insert Injection Molding,SKD61 Insert Injection Molding,738 molded rubber parts |

||

ABS / PC / PP Plastic Coffee Machine Part Injection Molding Household Appliance Cold Runner Injection Mold

Specifications

With over 17 years rich mould experience

Reasonable mould structure design

exquisite craftsmanship

modern techniques

Plastic coffee machine part injection molding household appliance coffee machine part mold

Product Description

1 . Injection molding

2 . precision machining plastic product

3 . Product & mold design

4 . standard OEM custom

mould making sheet

Name | injection mould making |

mould material | 45#,P20,H13,718,2738,NAK80,S136. |

mould base | LKM,HASCO |

Cavity | 1 or more |

Runner | cold or hot runner |

Mould life | 45# :300,000-500,000shots |

P20: 500,000shots | |

718: 700,000shots | |

Design software | UG,PROE,CADetc. |

Plastic material | PP,PE,ABS,PC PET pa66 . |

Delivery time | 25 days |

Specification | with good quality lower price |

mould making

1 . Samples/Drawing &Requirement from you

2 . Mould design:we will Communicate and Exchange the opinion with you after you place order.

3 . Material Purchase:Steel cutting and Mould base tooling.

4 . Assembling.

5 . Inspection of mould : following and controlling the tooling processing.

6 . Mould testing:We will inform you the date.Than will send the sample's inspection report&injection

parameters withthe sample to you!

7 . Your instruction &confirmation for shipment.

8 . Ready made mould before packing.

Following is also the essential informations, for customer reference

1 . Ready step | customer suppy us 3d drawing or sample .we make the injection mould drawing |

| |

2 . Negotiation | the quality, price, material, delivery time, payment item, |

| |

3 . Place an order | according to the confirmed plastc injetion mould drawing |

| |

4 . Mould | According to customers request to build the injection mould. Before make the mould, we send mould design to customer approval first, and cusotmer pay the deposit ..before move forward to production; we will send samples to customer to confirm first. |

| |

5 . Sample shoot | If the first sample come out is not satisfied customer, we will modify the mould till meet customers satisfactory. |

| |

6 . Products in store | If your quantity is beyond our storage, we will provide lead time to you. |

| |

7. Delivery time | Delivery goods by sea or by air, according to customers requirement. |

Our Services

Main service: injection mould, ruber mould, stamping mould.

What are our shipping service provided ?

1. WY mould can Load Container

2. WY mould provide shipping method :Courier Service, Air Transport, Sea Transport

3. WY mould accept order : Full Container Cargo Load , Less Container Load

4. WY mould provide service: EX-WORK ,FOB,CIF,C&F,Door to Door etc

What our payment terms ?

T/T, L/C, Western Union, Cash,Paypal ,E-Credit Line,Escrew

40% deposit,60% balance before delivery

Company Information

Our factory integrates mold design, manufacturing, and injection molding. It is a Director Unit of Weiyu Mold Industry Association, and a key backbone enterprise in Weiyu’s plastic mold industry.

Whats kind of a company we are ?

We a MANUFACTURER located DongGAN China .We were gainning good reputation among our

customers for our professional, warm and thoughtful service, Because we know that a long terms

business based on the quality control,prices,packing ,delivery time etc.

Does your company is a factory or trade company ?

We have a factory ourself , we are on this business for few years in China.

Whats the quality assurance we provided and how do we control quality ?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in

process materials, validated or tested materials, finished goods, etc. Besides, we have also developed

a procedure which identifies the inspection and test status of all items at all stages of the manufacturing

process.

What's your MOQ ?

MOQ is1 SET

About design

What is the key to making a product / mould successfully? Design is very important

Is design considerate for all details? Is the design fully satisfied all requirements of customer?

These are key factors for a successful mould /product design.

we will check customer data/specification carefully,

send a report of advice and manufacture ability let customer confirmation

After got the confirmation, we start designing mold construction and full 3D design.

fd mould always keep in touch with customer in every step, to ensure that all the details are in

accordance with customer request.

Ouradvantage

We should save you money through intelligent tooling design and efficient production run.

We have advanced CMM Machine, CNC Machine, EDM Machine, Wire-Cutting and other normal machine, the

injection machine from 20 ton to 1000 Ton. We can injection

almost any kind of plastics such as ABS, PC, PBT, ABS PC, PP, PMMA, PE, nylon, etc. The steel we

use for manufacturing moulds are P20, H13(fully hardened mould with HRC 52 54, 420 SS (Stainless

Steel),ETC or as specified by the customers.

![]()

![]()

![]()