-

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Mold Base | HASCO ,DME ,LKM,JLS Standard | Mold Hot Runner | DME, HASCO, YUDO,etc |

|---|---|---|---|

| Mold Strandard Parts | DME, HASCO, Etc. | Mold Life | >300,000 Shots |

| Mold Hot Treatment | Quencher, Nitridation, Tempering,etc. | Mold Cooling System | Water Cooling Or Beryllium Bronze Cooling, Etc. |

| Mold Surface | EDM, Texture, High Gloss Polishing | Equipments | High Speed CNC, Standard CNC, EDM, Wire Cutting, Grinder, Lathe, Milling Machine, Plastic Injection Machine |

| High Light | JLS ABS Plastic Injection Molding,GPS ABS Plastic Injection Molding,Custom Plastic Molding 300 000 shots |

||

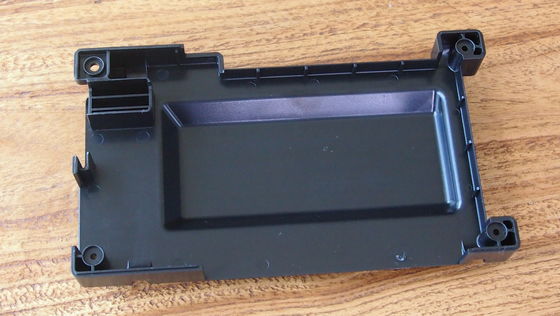

ABS Plastic Injection Mold For GPS Case Shell Tooling , Custom Plastic Molding

| Product description | ||

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc | |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. | |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production | |

| Certificate | ISO 9001:2008 | |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. | |

| Plastic production Raw material | PP,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc | |

| Mold base | HASCO ,DME ,LKM,JLS standard | |

| Mold runner | Cold runner, hot runner | |

| Mold hot runner | DME, HASCO, YUDO,etc | |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. | |

| Mold strandard parts | DME, HASCO, etc. | |

| mold life | >300,000 shots | |

| Mold hot treatment | quencher, nitridation, tempering,etc. | |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. | |

| Mold surface | EDM, texture, high gloss polishing | |

| Hardness of the steel | 20~60 HRC | |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine | |

| Lead time | 25~30 days | |

| Month Production | 50 sets/month | |

| Mold Packing | standard exporting Wooden case | |

| Injection molded parts Description | ||

| Design software | UG, ProE, Auto CAD, Solidworks, etc. | |

| Certificate | ISO 9001:2008 | |

| Plastic production Raw material | PP,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR, silicone rubber,etc (flame retardant, UV as optional) | |

| molded parts size | As per your drawing or samples | |

| Color | According to your Panton number color or your samples | |

| parts finish | painting, chrome, silk sreen, thermo printing, etc. | |

| Molded Parts features | Free of flash, sink mark, blemishes, variation, etc. | |

| Parts application | Automative, Industrial, Household applicance, Vehicle, Medical, Food processing, Agriculturaletc. | |

| lead time | 1 week | |

| Packing | bulk or individual pack, upon customer's demands with exported carton box. | |

About Us

Weiyu plastic mold Co., Ltd. was established in 1993. We provide service for subcontract manufacturing for components of household and industrial electronic devices and similar products which use plastic, metal and rubber materials. Our main task to provide competent manufacturer according to our customer's task, solve problems at preproduction process and quality control of the finished production

Our main product lines are moulds for plastic, metal and rubber components of household and industrial electronic devices, plastic toys for children, educational devices and talking pen for children and adults, plastic products for advertisement, car parts, etc.

To provide our customers best quality and reliability of production we make strict quality control from the beginning of drawing conformation until the final packaging. We use safe high-quality materials and work with experienced factories.

We are an experienced and professional team, we have export our products to many countries and regions all over the world. Our products enjoy good popularity among our customers. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.![]()

Why choose us?

· Manufacturing and exporting experience for over 20 years. ISO 9001 approved.

· Products are supplied to over 50 countries.

· One-stop service for aluminum profiles, plastic parts, rubber parts, and moulds. Save time and save money for you.

· In-house mold design and building capabilities.

· No reclaimed material used to ensure high quality.

· Keep secret to your idea and your design.

· Professional design team, mold maker engineer. OEM/ODM service.

· Professional QC and R&D teams to assure high quality.

· Professional sales team. Good English capabilities and communication skills.

· No MOQ.

· Prompt delivery. For prototype: 3-7 days. Production orders can be arranged specially to meet customer’s urgent demands.

· Geographical advantages: within 30 minutes to airport or sea port.

·![]()

·

| Q1. When can I get the price? |

| A: We usually quote within 24 hours after we get your inquiry. Or please call us or send us email so that we will make the quotation soonest. |

| Q2. How long is the lead-time for mold? |

| A: It all depends on the mold’s size and complexity. Normally, the lead time is 25-35days. If the molds are very simple and with small size, we can work out within 15 days. |

| Q3. I have no 3D drawing, how should I start the new project? |

| A: You can supply us a sample, and we will help to finish the 3D drawing design. |

| Q4. Before shipment, how to make sure the products quality? |

| A: We will supply you a video for production process detail include process report, products size ,structure and surface detail, packing detail and so on. |